In the future, Tichawa Vision will manufacture the sensor boards in-house

The heart of our products are the sensor boards. These carry the sensor chips, which scan the image in a similar way to a line scan camera. The difference to a line scan camera is that many sensor chips have to be lined up in a CIS for the scan width. The chips are “bonded” directly onto a PCB using the COB (Chip on Board) process. A sensor board is 260 mm long. In order to achieve the entire scan width, several of these sensor boards are lined up. Thus, depending on the CIS length, there are one to 16 sensor boards in one unit.

We have gained a lot of experience over many years with external service providers about this not entirely uncritical part of the manufacturing process, and are now familiar with all the challenges in this context. The bonding of optical components is a very special challenge, because not only the electrical connections have to be perfect but also the mechanical positioning in the previous step, the “die bonding”, has to be very exact.

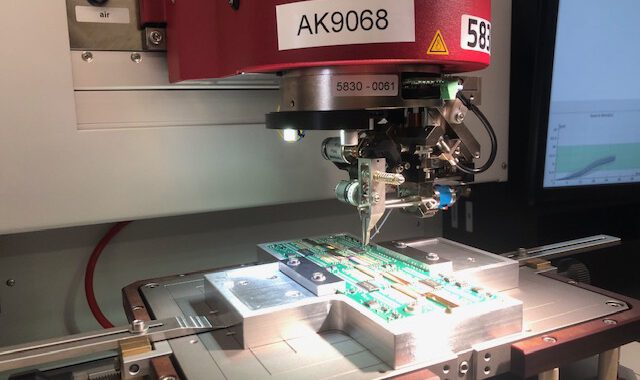

Now we have decided to bring the bonding process in-house as well. For this purpose, we have purchased a wire bonder from the Austrian company #F&S BONDTEC and are currently in the process of setting up a suitable bonding room. Our production staff have already been trained. Starting in the fall, our new wirebonder will go into series production and will bond some of our sensor boards in the future.

We want to use it to shorten production time, improve quality, reduce costs, and achieve greater flexibility.