Properties of VUCIS

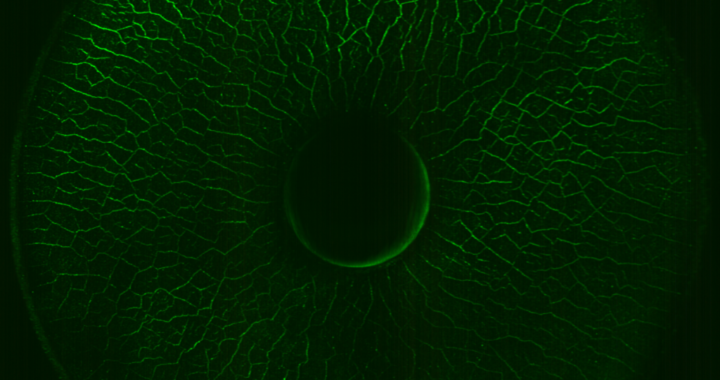

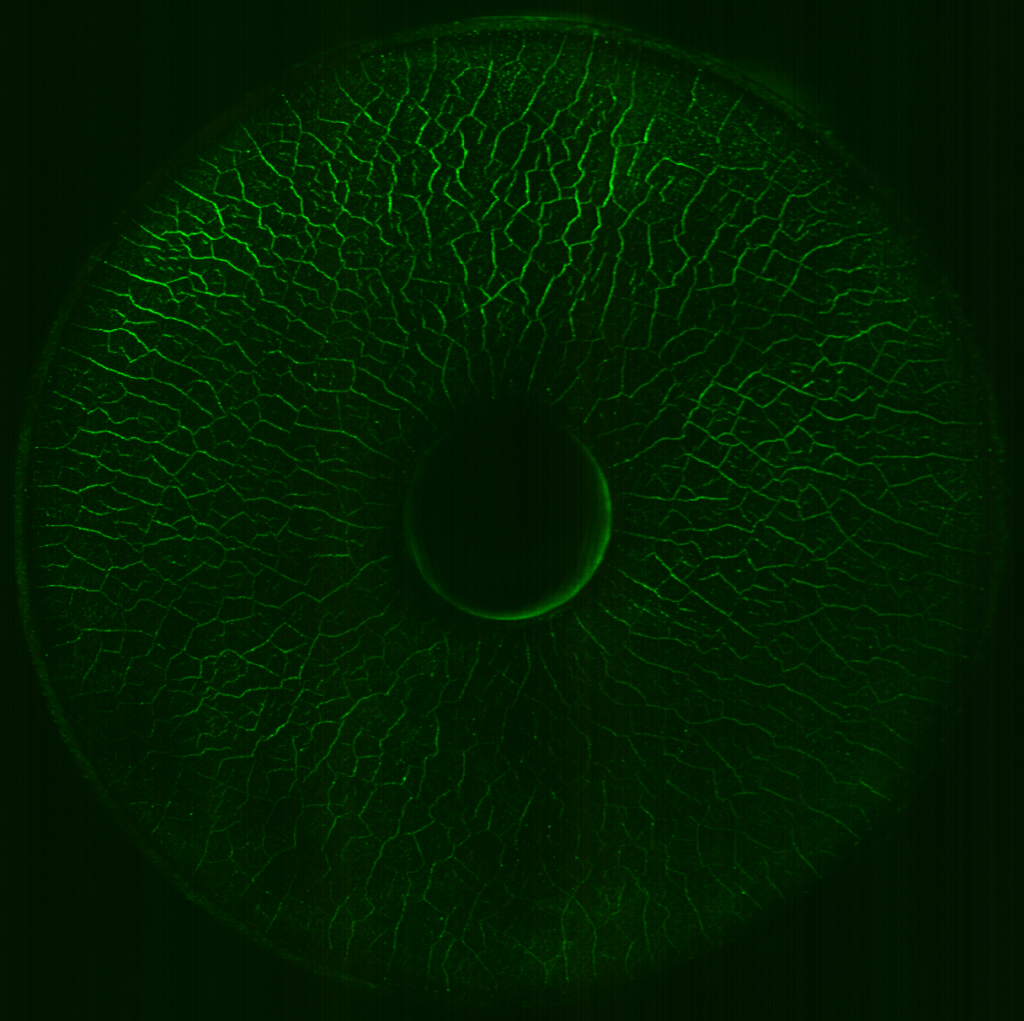

Magnetic particle inspection is a non-destructive testing method used to identify cracks and defects in magnetic materials. In this method, a fine magnetic powder is applied to the surface of the workpiece. The powder accumulates in the cracks and makes them visible. By using UV light as an illumination source, the cracks can be recognised even more clearly, as the light makes the magnetic powder glow and thus highlights the cracks.

The VARI Universal CIS (VUCIS) is a special illumination system developed for magnetic particle inspection. It provides uniform and intense illumination to ensure a clear view of the cracks. This system enables inspectors to perform precise inspections and detect potential defects at an early stage, which helps to improve the quality and safety of components. Magnetic particle inspection is an important part of many industries, including aerospace, automotive and mechanical engineering.