With its latest industrial CIS scanner, Tichawa Vision GmbH introduces a new development in industrial image processing. Using Shape-from-Shading/Photometric Stereo technology, the system enables precise 3D inspection of surface structures at high speed, optionally in colour. This makes it possible to visualize fine 2D and 3D material structures even on dark or reflective surfaces and […]

Category Archives: CIS

All posts about our Contact Image Sensors

Inspection of Battery Films

Inspection of the lithium surface by VacuumCIS possible! Battery films are extremely thin, flexible and conductive materials used in batteries to maintain the various layers of insulation and electrical contact between the components. They typically consist of several layers, including a conductive layer, a separator layer and a protective layer. Defects in battery films can […]

Magnetic particle inspection

Properties of VUCIS Magnetic particle inspection is a non-destructive testing method used to identify cracks and defects in magnetic materials. In this method, a fine magnetic powder is applied to the surface of the workpiece. The powder accumulates in the cracks and makes them visible. By using UV light as an illumination source, the cracks […]

Patent certificate for BoroCIS

Protection for BoroCIS against imitations We are pleased to announce that after a long wait, the patent for our innovative BoroCIS has finally been approved by the Munich Patent Office. This ground-breaking technology, in combination with our patented RingCIS, enables our customers to carry out a comprehensive internal and external inspection of pipes, tubes and […]

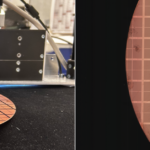

Wafer inspection with Contact Image Sensor

Special requirements for the inspection of wafers Optical wafer inspection plays an important role in semiconductor production in order to manufacture microchips with flawless quality. Optical systems are used to detect scratches, defects or particles on wafers.The requirements placed on the camera system used for this are very demanding. A high resolution is required to […]

New product key for various illuminations

Change of product key from VTCIS to VUCIS Tichawa Vision is changing the type code for the latest Contact Image Sensor generation. Due to many new innovative developments in the field of lighting and optics, this is the ideal time to make the key a little more intuitive. The key changes from VTCIS to VUCIS […]

VUCIS Illumination Scheme

The Tichawa Vision VUCIS combines a built-in intelligent programmable ultra high speed Illumination Controller with a wide choice of illumination colors and geometries to get the best possible images for conventional or AI based Image Processing. The Illumination Controller is built around a phase sequencer and a Color Mix Table, both completely under user control. […]

How does a pipe get inspected inside and outside during the production process?

4 methods for the inspection of pipes, tubes and profiles Tichawa Vision offers five CIS products for the inspection of tubes, pipes and profiles. Inspection on the outside: Why CIS? There are a lot of Line Scan Camera solutions available for image acquisition of rotating objects. However, if you want to inspect a pipe with […]

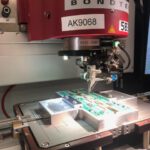

Chip on Board at Tichawa Vision

In the future, Tichawa Vision will manufacture the sensor boards in-house The heart of our products are the sensor boards. These carry the sensor chips, which scan the image in a similar way to a line scan camera. The difference to a line scan camera is that many sensor chips have to be lined up […]

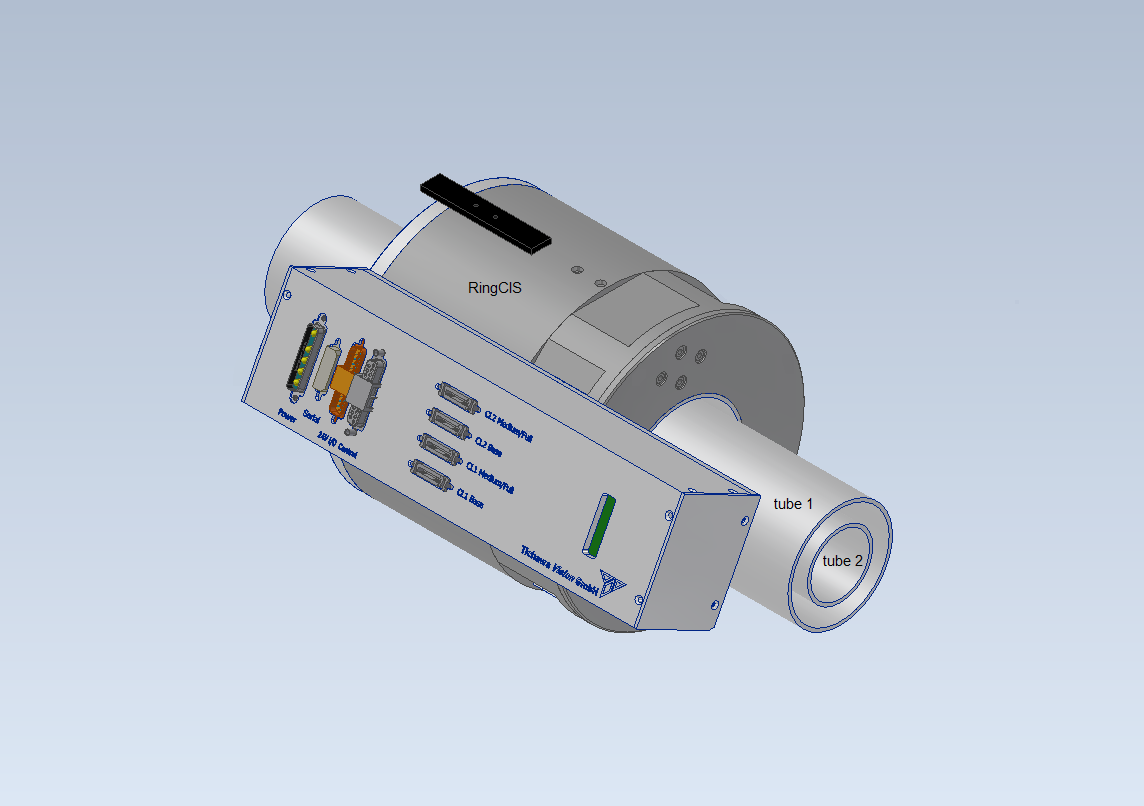

New design for RingCIS – Adjustable for different tube diameters

For the RingCIS with adjustable focus the design and construction is completed. From now on it is possible to use the same RingCIS for different tube diameters. For lines where different types of tubes are processed you can use your quality control with only one RingCIS. This requires only a simple adjustment of the head when […]